|

Design

Glandless circulation pump with screwed connection or flange connection.

Application

Hot-water heating systems of all kinds, industrial circulation systems, air-conditioning systems and closed cooling circuits

Type key

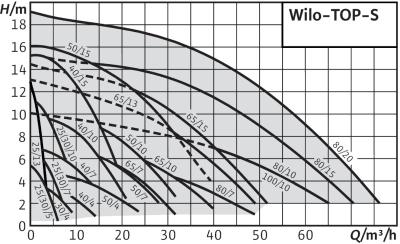

| Example: | TOP‐S 40/10 | | TOP-S | Standard pump (screw-end pump or flange-end pump) | | 40/ | Nominal connection diameter | | 10 | Nominal delivery head [m] at Q = 0 m3/ h |

Special features/product advantages

- Collective fault signal as potential-free contact (depending on type)

- Direction of rotation indicator light for displaying the correct sense of rotation (only with 3~)

- Pump housing with cataphoretic (KTL) coating protects against corrosion due to condensation formation

Technical data

- Permitted temperature range -20 °C to +130 °C,

for short periods (2 h) up to +140 °C (TOP-S 25/13, 80/15, 80/20 and pumps with Wilo-Protect-Module: -20 °C to +110 °C) - Mains connection:

- 1~230 V, 50 Hz (depending on type)

- 3~230 V, 50 Hz (with optional switching plug)

- 3~400 V, 50 Hz

- Protection class IP X4D

- Screwed connection or flange connection (depending on type) Rp 1 to DN 100

- Max. operating pressure, standard version: 6/10 bar or 6 bar (special version: 10 bar or 16 bar)

|

Equipment/function

Operating modes Manual functions - Setting of the speed stages: 3 speed stages (2 speed stages for 1~pumps with P2 ≥ 350 W)

Automatic functions - Full motor protection with integrated trip electronics (standard equipment only for 3~pumps with P2 ≥ 180 W and 1~pumps with P2 ≥ 350 W, optional for all types with Wilo-Protect-Module C)

External control functions - "Overriding Off" control input (optional for all types with Wilo-Protect-Module C)

Signal and display functions - Individual/collective fault signal (potential-free NC contact) (optional for all types with Wilo-Protect-Module C)

- Collective fault signal (potential-free NC contact) (standard equipment only with 3~ pumps with P2 ≥ 180 W and 1~ pumps with P2 ≥ 350 W, optional in all types with Wilo-Protect-Module C)

- Individual run signal (potential-free NO contact) (optional for all types with Wilo-Protect-Module C)

- Thermal winding contact (WSK, potential-free NC contact) (only for 1~pumps with P2 = 180 W)

- Fault signal light (standard equipment only for 3~pumps with P2 ≥ 180 W and 1~pumps with P2 ≥ 350 W, optional for all types with Wilo-Protect-Module C)

- Direction of rotation control light (only for 3~pumps )

Dual pump management (double pump or 2 x single pump) - Main/standby mode (automatic fault-actuated switchover/time-dependent pump cycling): optional for all types with Wilo-Protect-Module C

Equipment - In flange pumps: Flange versions

- Standard version for pumps DN 40 to DN 65: Combination flange PN 6/10 (flange PN 16 acc. to EN 1092-2) for counter flanges PN 6 and PN 16,

- Standard version for pumps DN 80 / DN 100: Flange PN 6 (configured for PN 16 acc. to EN 1092-2) for counter flange PN 6,

- Special version for pumps DN 40 to DN 100: Flange PN 16 (acc. to EN 1092-2) for counter flange PN 16,

- Cable lead-in possible from both sides (only for 1~pumps and 3~pumps with P2 ≥ 180 W)

- Standard thermal insulation for heating applications

Materials

- Pump housing: Grey cast iron

- Impeller: Plastic

- Shaft: stainless steel

- Bearing: Carbon, metal impregnated

Scope of delivery

- Pump

- Thermal insulation

- Including seals for threaded connection

- Washers for flange screws (for nominal connection diameters DN 40 ‐ DN 65)

- Installation and operating instructions

Options

- Special version for operating pressure PN 16 (at additional charge)

- Version for special voltages on request.

Accessories

- Screwed connections for threaded connection

- Counter flanges for flange connection

- Adapter fittings

- For pumps 3~400 V:

- Switching plug 3~230 V, 50 Hz (not TOP-S 80/15, TOP-S 80/20)

- Wilo-Protect‐Module C, 3~400 V

- For pumps 1~230 V:

- Wilo-SK 602N/SK 622N tripping unit for full motor protection

- Wilo-Protect‐Module C, 1~230 V

|